Thermostat Model ISQB is the best suited thermal cutout for over temperature protection of battery chargers.

Thermostat for Battery Charger – Model ISQB

Description of Thermostat/Thermal Overload Protector

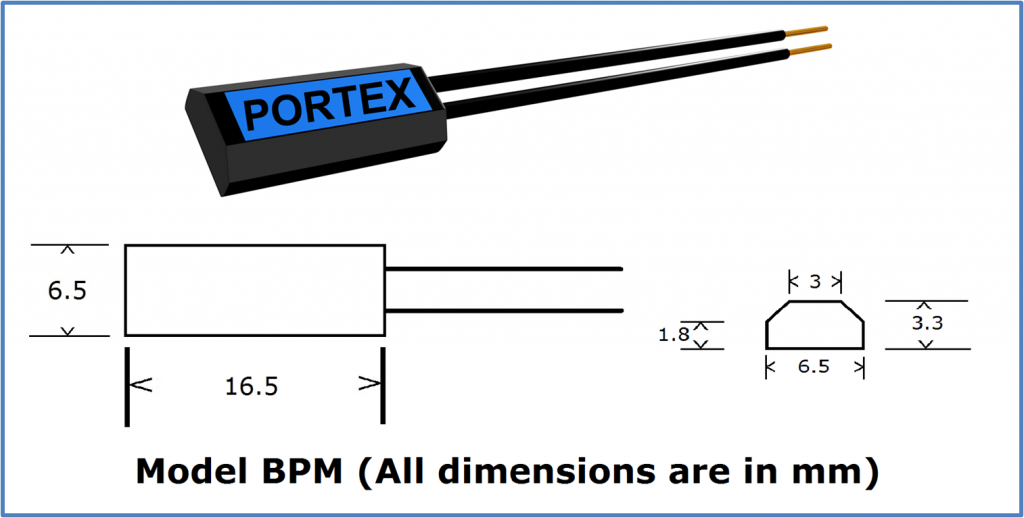

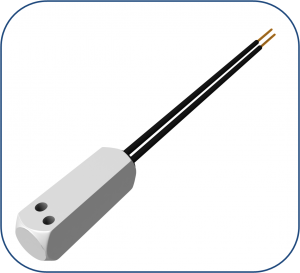

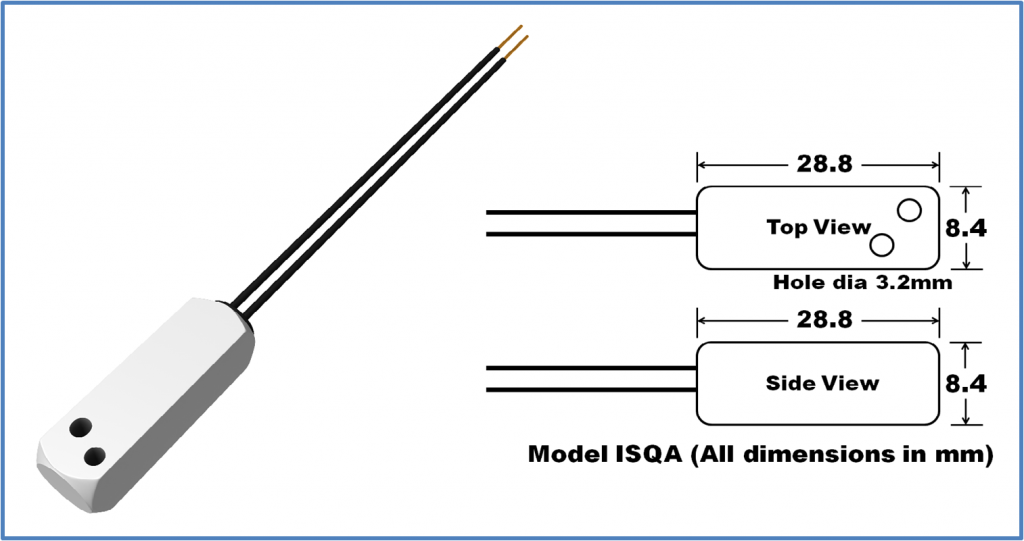

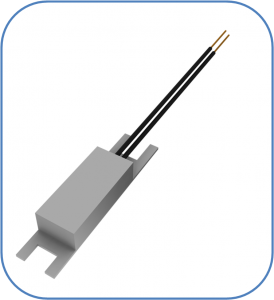

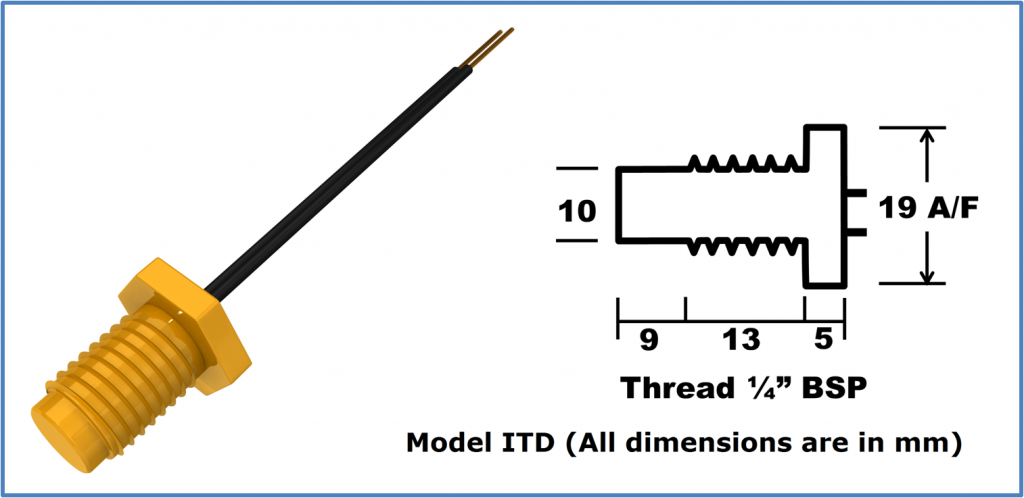

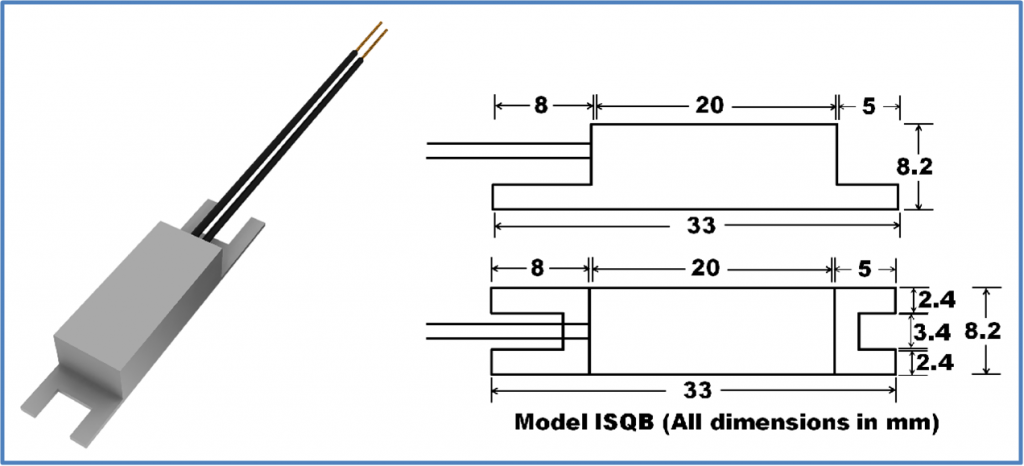

Model ISQB thermostat has been developed by our engineering team after extensive R&D for over temperature protection of Battery Chargers. This thermal overload protector has an outer body machined from solid aluminum rod. This provides the thermostat with better heat sensing capability and greater strength. Unlike other thermal cutouts, this aluminum body is electrically insulated, so there is no chance of an electrical shock. This thermal overload protector can be easily mounted with two screws as it has grooves on both ends. Unlike normal snap action disc thermostats, which have delayed restart and in which the trip temperature drifts downwards, our thermal overload protector operate on the over center mechanism with a snap action bimetal and a copper alloy switching blade. This provides the thermostat with quick restart characteristic and stable trip temperature, even after continuous usage. The contacts are made of solid silver for long life. The lead wires are teflon insulated and can withstand high temperature. The body is sealed and resistant to dust, fumes, varnish, moisture, etc. This thermal cutout can is available with both Normally Open (N.O.) or Normally Closed (N.C.) contacts.

Special Features:

-

- Aluminum body for strength

- Better heating sensing capability

- Solid Silver contacts for long life 1,00,000 operations

- Easily mountable with two screws

- Snap action bimetal thermostat

- Quick make & break switching, no chattering

- Available in Normally Open (N.O.) or Normally Closed (N.C.) contacts

- Available in any temperature from 50C to 160C

Application of Thermostat/Thermal Overload Protector

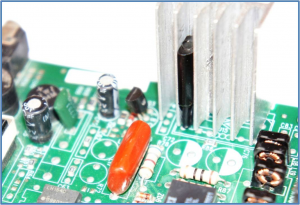

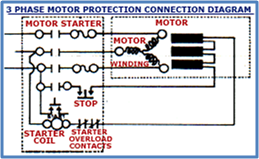

This thermostat can be screwed to any heat sink in the battery charger or on to the body of the charging transformer. When the battery chargers heats up, this thermostat will sense the temperature rise and the bimetal will snap open the contacts at the preset trip temperature. This will disconnect the battery charger from the mains and prevent it from overheating. The trip temperature of the thermal cutout is preset at the time of manufacturing and cannot be changed.

The Normally Open (NO) contacts thermostat can be used to operate a fan when the battery charger overheats. When the equipment heats to the desired trip temperature, the contacts of the thermal overload protector will snap close and this can switch on the fan to cool the battery charger. This can also be used to provide a signal of overheating by operating a control circuit or signal lamp. Please consult us for complete technical guidance.

| Voltage | Up to 250VAC or 24VDC |

| Continuous Load | Up to 8 AMPS |

| Maximum Load Switching Capacity | 30 AMPS |

| Contacts Configuration | Available with Normally Open (N.O.) or Normally Closed (N.C.) contacts |

| Switching Action | SPST Normally Closed (N.C.) or Normally Open (N.O.) contacts which open or close with a snap action at a preset temperature and disconnect the battery charger from the mains. |

| Flash-over Voltage | Exceeds 2 KV between body & leads. |

| Endurance (Life) | Exceeds 100,000 operations (trippings). |

| Trip Temperature | Available preset for any trip temperature between 50 ± 5 C to 160 ± 5 C specified by customer. Trip temperature not adjustable. |

| Reset Temperature | Reset temperature (restart temp) approx. 15 ± 5 C below trip temperature. |

| Restart Mode | Thermostat/thermal overload protector will automatically restart upon cooling and will automatically switch on the battery charger and restore the power supply. |

| Fitting or Mounting | The thermostat/thermal overload protector can be screwed on to the body of the battery charger where it can sense temperature rise, or, it can be screwed on to any heat sink. |

| Connections | Thermostat/Thermal Overload Protector can be connected in series with the main circuit of the battery charger so that it disconnects the power supply when it trips off. It can also be connected to a control circuit, relay, contactor, etc., which can provide an indication of overheating. It can also be connected to a fan which will operate when the battery charger overheats. |