We are the leading manufacturers and suppliers of thermostats for gas pre-heaters and have been supplying thermostats to this industry for the last 25 years. Almost all manufacturers of various gas pre-heaters (especially Advani-Oerlikon type design) use our thermostat model ISQA due to its durability, strength and stable trip temperature over a long period of continuous usage.

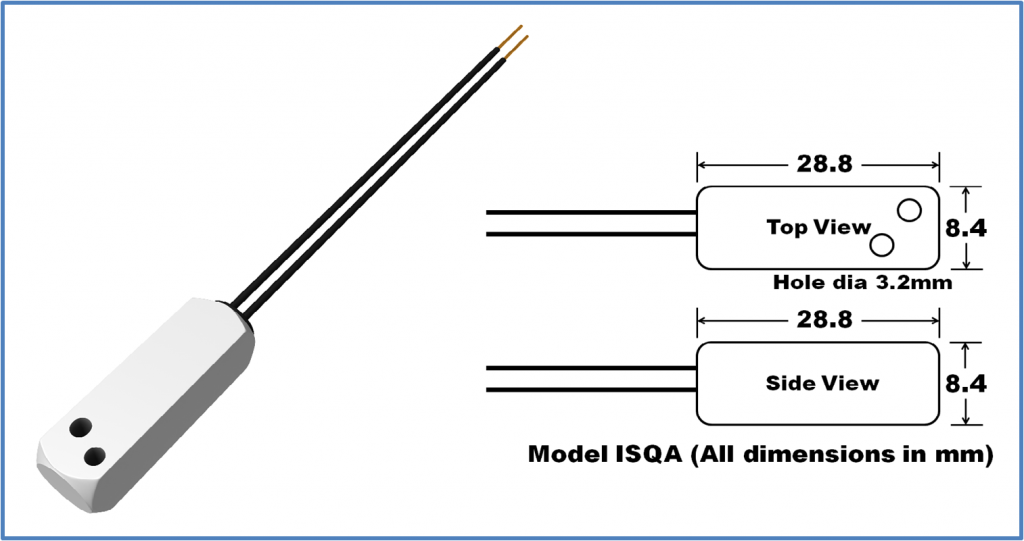

Gas Pre-heater Thermostat – Model ISQA

Description of Thermostat/Thermal Overload Protector

Model ISQA thermal overload protector acts as a thermostat and heats the cold welding gas to the desired temperature. This thermostat model has a solid aluminum body for greater strength and better heat sensing capability. This thermostat has two holes by which it can be easily mounted on to the body of the gas pre-heater. The aluminum body is electrically insulated. So there is no chance of any electrical shock. The internal contacts of the thermostat are made of sold silver for long life. The internal mechanism is all spot welded on a stainless steel housing plate. The lead wires are Teflon insulated and can withstand high temperature. The body of the thermostat is double sealed with high temperature epoxy, so the operating characteristics is not affected by dust, moisture, varnish, etc.

Normal snap action disc thermostats have delayed restart and the trip temperature drifts downwards after long usage. Our thermostats have a snap action bimetal and a beryllium copper switching blade which operate on the over center mechanism. This provides the thermostat with quick restart characteristic and stable trip temperature, even after long usage of many years.

Special Features:

- Solid Aluminum body of strength

- Better heat sensing capability

- Solid silver contacts for long life of 1,00,000 operations

- Snap action bimetal thermostat

- Teflon insulated lead wires

- Available in any temperature from 50C to 160C

Application of Thermostat

This thermostat has to be mounted inside the gas pre-heater with two screws. It should be fitted close to the heating element so that it can sense the temperature rise quickly. This thermostat maintains the temperature of the welding gas in the desired temperature range. When the temperature of the heater rises, the thermostat senses this rise and trips off, thereby, switching off the heater and preventing overheating. Subsequently, when the heater cools down, the thermostat switches on and restarts the heater. After which it again switches off/on and maintains the desired temperature range. This temperature range is fixed at the time of manufacturing and cannot be changed. It is specified by the customer. Normally most customers are using 120C thermostat model ISQA. Please consult us for complete technical guidance.

| Voltage | Up to 250VAC or 24VDC |

| Continuous Load | Up to 8 AMPS |

| Maximum Load Switching Capacity | 30 AMPS |

| Contacts Configuration | Available with Normally Closed (N.C.) |

| Switching Action | SPST Normally Closed (N.C.) contacts which open or close with a snap action at a preset temperature and disconnect the gas preheater from the mains. |

| Flash-over Voltage | Exceeds 2 KV between body & leads. |

| Endurance (Life) | Exceeds 100,000 operations (trippings). |

| Trip Temperature | Available preset for any trip temperature between 50 ± 5 C to 160 ± 5 C specified by customer. Trip temperature not adjustable. |

| Reset Temperature | Reset temperature (restart temp) approx. 15 ± 5 C below trip temperature. |

| Restart Mode | The thermostat/thermal overload protector will automatically restart upon cooling and this will automatically switch on the gas preheater. |

| Fitting or Mounting | The thermostat/thermal overload protector can be screwed on to the body of the gas preheater or near the heating element so that it can sense the temperature rise. |

| Connections | Thermostat/Thermal Overload Protector can be connected in series with the heater. |