From our complete range of thermostats, Model BPM thermal overload protector is the best suited thermostat for over temperature and burnout protection of Coils and Solenoids.

Thermostat for Coils & Solenoids – Model BPM

Description of Thermostat/Thermal Overload Protector

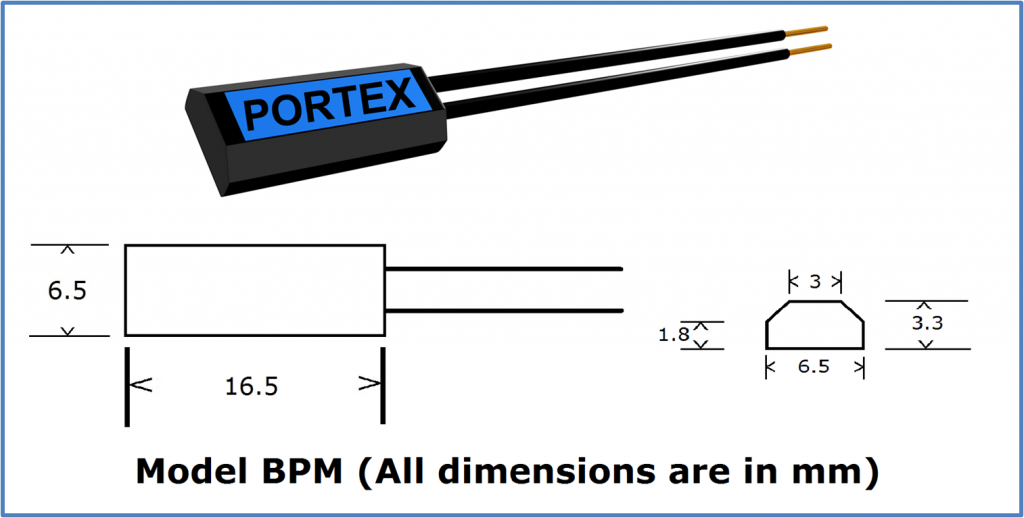

Model BPM thermostat is manufactured in our manufacturing facility in India. This thermal overload protector has been developed after extensive research and development by our engineers as the smallest thermostat in our entire range of thermostats. Due to the small size of the thermostat, it can be easily taped or fixed on to coils and solenoids where space is a constraint. This thermostat has an outer body which is made of an engineering polymer which can withstand high temperature. The internal contacts are made of solid silver. This ensures that the thermostat has a long life. All the internal components are spot welded on a stainless steel housing plate. The body of the thermostat is sealed so that the operating characteristics are not affected by dust, moisture, etc. Due to the sophisticated engineering and research, this model is available with Normally Open (NO) or Normally Closed (NC) contacts.

The operating principle of our thermostats is based on the over center mechanism which operates a snap action bimetal and a beryllium copper switching blade. Due to this there is quick restart and stable trip temperature. In the normal snap action disc thermostats, the trip temperature drifts downwards after continuous usage and there is delayed restart.

Special Features:

- Smallest size for easy fitting

- Bimetallic Snap Action Thermostat

- Available in Normally Open (NO) or Normally Closed (NC) contacts

- Accurate an Precise Operation

- Chattering free and no sparking

- Quick make and break switching action

- Solid silver contacts for long life of 1,00,000 operations

- Available in any temperature from 50C to 160C

Application of Thermostat/Thermal Overload Protector

The function of Model BPM thermostat is to prevent overheating. So it needs to be fixed or taped onto the coil or solenoid such that when the heat builds up, it can sense the rapid temperature rise and trip off. This thermal overload protector needs to be connected in series with the coil or solenoid. For switching high ampere loads in the coil or solenoid, the thermostat needs to be connected to a relay, contactor or control circuit. When the temperature rises to the cut-off point, the thermostat will trip off, thereby, disconnecting the coil and solenoid from the mains, or it can provide a signal to the relay or control circuit to disconnect the mains. Please consult us for complete technical advice.

| Voltage | Up to 250VAC or 24VDC |

| Continuous Load | Up to 8 AMPS |

| Maximum Load Switching Capacity | 30 AMPS |

| Contacts Configuration | Available with Normally Open (N.O.) or Normally Closed (N.C.) contacts |

| Switching Action | SPST Normally Closed (N.C.) or Normally Open (N.O.) contacts which open or close with a snap action at a preset temperature and disconnect the coil or solenoid from the power supply. |

| Flash-over Voltage | Exceeds 2 KV between body & leads. |

| Endurance (Life) | Exceeds 100,000 operations (trippings). |

| Trip Temperature | Available preset for any trip temperature between 50 ± 5 C to 160 ± 5 C specified by customer. Trip temperature not adjustable. |

| Reset Temperature | Reset temperature (restart temp) approx. 15 ± 5 C below trip temperature. |

| Restart Mode | The thermostat/thermal overload protector will automatically restart upon cooling. This will automatically switch on the coil or solenoid and restore current flow. |

| Fitting or Mounting | The thermostat/thermal overload protector can be taped on the coil or solenoid with a high temperature resistant tape. |

| Connections | Thermostat/Thermal Overload Protector can be connected in series with the main power supply of the coil or solenoid. For heavy loads use a relay or contactor. |