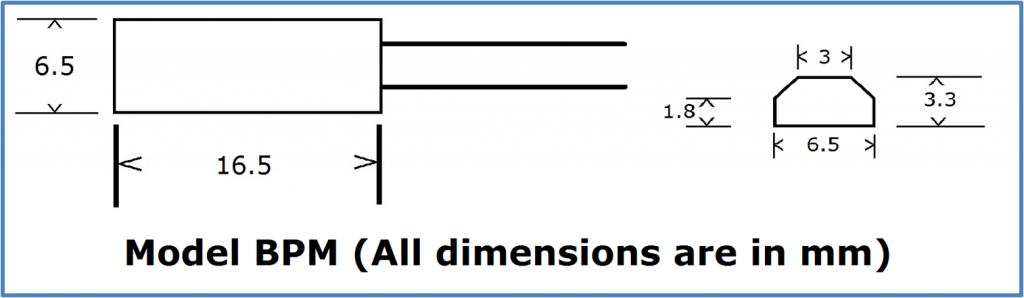

Thermal Overload Protector

Thermal Overload Protector Model BPM is a marvel of precision engineering and miniaturization, developed by Portex Technologies, India’s Leading Manufacturer and Supplier of Thermal Overload Protectors and Thermal Cutouts. Model BPM is the smallest thermal overload protector in our entire range of thermostats, specifically designed for over temperature protection of electronic and electrical equipment. This thermal overload protector is available with Normally Closed (NC) or Normally Open (NO) contacts. Due to small size, the response to temperature rise is fast, and when the equipment overheats, the thermostat trips off, ensuring complete protection to all equipment against burning or over heating.

Thermal Overload Protector inside Motor Winding

The outer body of this thermal overload protector is made of a high temperature engineering polymer and the contacts are made of solid silver for long life. The lead wires are teflon insulated and can withstand high temperature. This body is sealed with high temperature epoxy and so the operating characteristics are not affected by dust, fumes, varnish, etc. The operating principle of this thermal overload protector is based on the over center mechanism. This mechanism operates a snap action bimetal and a beryllium copper switching blade. This provides the thermal overload protector with quick make and break switching characteristic, stable trip temperature, even after continuous usage, and quick restart. The normal snap action disc thermostats have delayed restart and the trip temperature drifts after long usage.

Special Features of Thermal Overload Protector

- Snap Action bimetal thermostat

- Quick make and break switching

- Small size for easy fitting

- Chattering free and precise operating characteristics

- Solid silver contacts for long life of 1,00,000 operations

- Sealed body resistant to moisture, gases, fumes and varnish

- Lead wires are teflon insulated

- Available for any trip temperature required from 50 degrees C to 160 degrees C

Technical Specifications of Thermal Overload Protector

| Voltage | Upto 250 VAC or 24 VDC |

| Continuous Load | Upto 8 AMPS |

| Maximum Load Switching Capacity | 30 AMPS |

| Switching Action | SPST Normally Closed (N.C.) contacts which open with a snap action. Also available Normally Open (N.O.) contacts which close with a snap action. |

| Flash-over Voltage | Exceeds 2 KV between body & leads. |

| Endurance (Life) | Exceeds 100,000 operations (trippings). |

| Trip Temperature | Available preset for any trip temperature between 50 ± 5 C to 160 ± 5 C specified by customer. Trip temperature not adjustable. |

| Reset Temperature | Reset temperature (restart temp) approx. 15 ± 5 C below trip temperature. |

| Restart Mode | Automatic restart upon cooling. Adequate precaution must be exercised in applications where automatic restart can cause injury, i.e., power tools, mixie blade, power saws, machinery etc. |

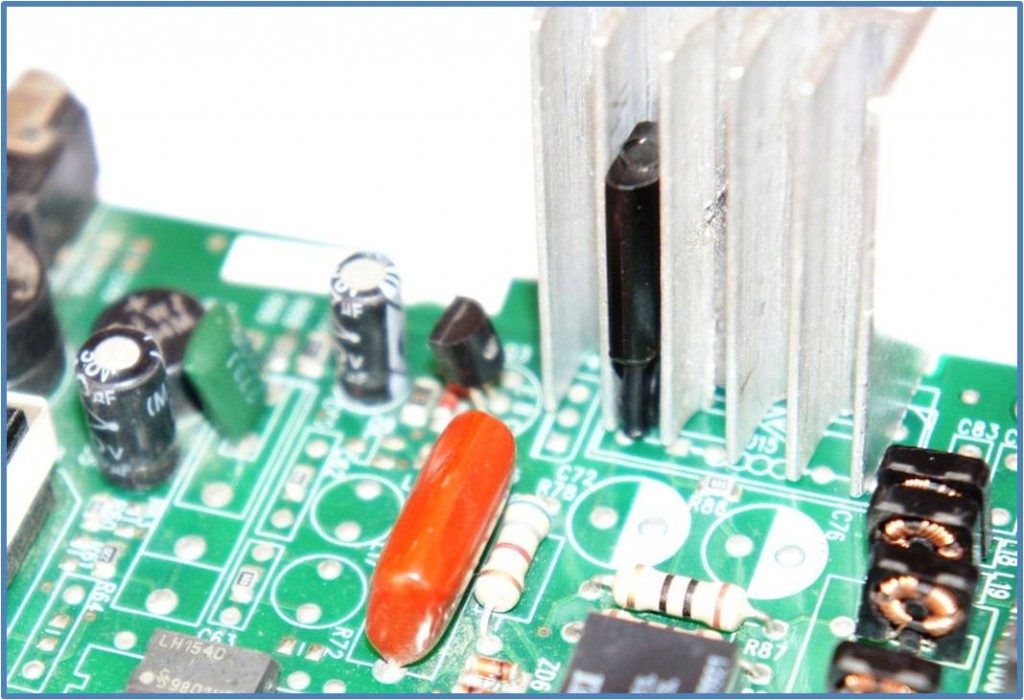

Heat Sink with Thermal Overload Protector inside Circuit

Applications of Thermal Overload Protector

- Rechargeable Battery Pack Protection

- Home Appliances

- Motor overheat & burnout protection – all sizes (single and three phase)

- Heating pads and Electric Blankets

- Heat sink over-temperature sensor

- Transformer overheat & burnout protection (all sizes)

- Bearing and bushes overheat sensors

- Industrial electronics: overheat protection of thyristors, power transistors, SCRs, etc.

- Industrial machinery thermostat

- Coils, solenoids and electromagnets