We are the leading manufacturer of Thermostat and Thermal Overload Protectors in India and we have developed two models of thermal overload protectors, i.e. Model BPM and Model ISQB, for over temperature and burnout protection of Transformers.

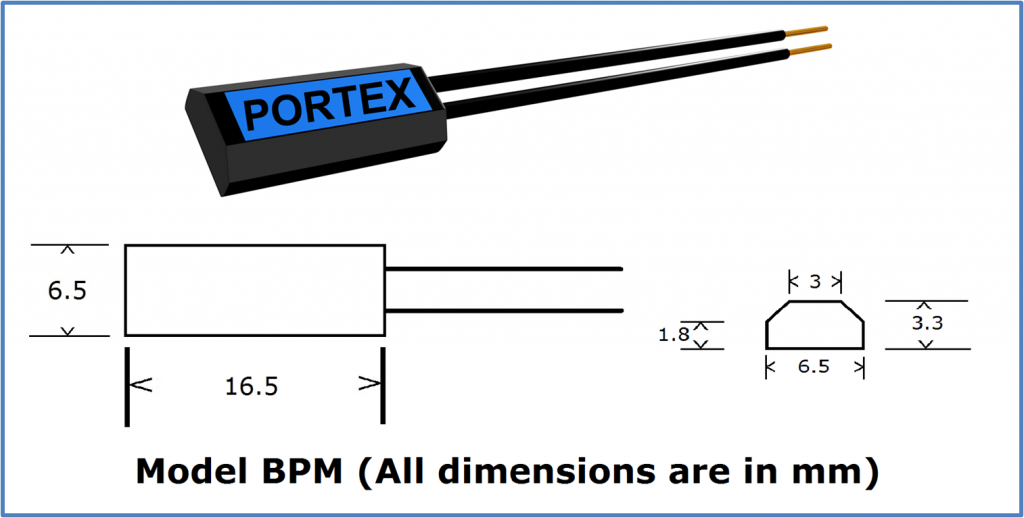

Transformer Protection Thermostat – Model BPM

Description of Model BPM

Model BPM thermal overload protector has been specifically developed for over temperature and burn-out protection of transformers, where the thermostat has to be fitted inside the windings. This thermal overload protector is a miniature marvel of precision engineering and it is the smallest thermal cut-out in our complete range of products. Due to its small size, this thermostat is very sensitive to temperature rise and ampere load and can be fitted inside the winding. As soon as the windings start heating up, this thermal cut-out senses the temperature rise and switches off at the pre-determined cutoff temperature, thereby, protecting the transformer from overheating or burning out . This pre-determined cutoff temperature is factory preset and cannot be changed. This thermostat has solid silver contacts for long life. The internal operating mechanism is all spot welded on a stainless steel housing plate. The outer body of this thermal overload protector is a high temperature resistant engineering polymer.

Out thermostats have a snap action bimetal strip and a beryllium copper switching blade which operate on the over center mechanism. This provides the thermostat with a quick restart characteristic, accurate trip temperature. This trip temperature does not drift downwards after long usage. The other snap action disc thermostats have delayed restart and the trip temperature does not stay stable and drifts downwards after continuous usage.

Special Features of Thermal Overload Protector:

- Smallest physical size, easy to fit

- Very sensitive to temperature rise

- Snap action bimetal quick make and break action

- Solid silver contacts for long life of 1,00,000 operations

- No sparking or chattering of contacts

- High temperature resistant teflon lead wires

- Available for any trip temperature from 50C to 160C

Application

Model BPM thermostat is suitable for over temperature and burnout protection of transformers of all types. This thermal overload protector should be fitted inside the windings of the transformer. It can be fitted either in the primary side or secondary side of the transformer, which ever winding is heating up. When a fault condition occurs and the temperature of the transformer winding rises, the thermostat will sense this rise and switch off, thereby, protecting the transformer from burnout. For protection of small transformers with low power ratings, the thermal cut-out can be connected in series with the winding. For protection of large transformers with high power ratings, the thermal overload protector cannot be connected in series as the high current can damage the cut-out or it will cause nuisance tripping. The thermal cut-out needs to be connected to a relay, contactor, indicator, or control circuit, which will switch off the transformer when the thermal cut-out reaches its cutoff temperature and trips off. This cutoff temperature is pre-determined and cannot be changed. It depends on the insulation class of the windings as well as the size of the transformers, for example, insulation class B the trip temperature should be 130 degrees C and for insulation class F the trip temperature should be 150 degrees C. Please consult us for technical guidance and specifications.

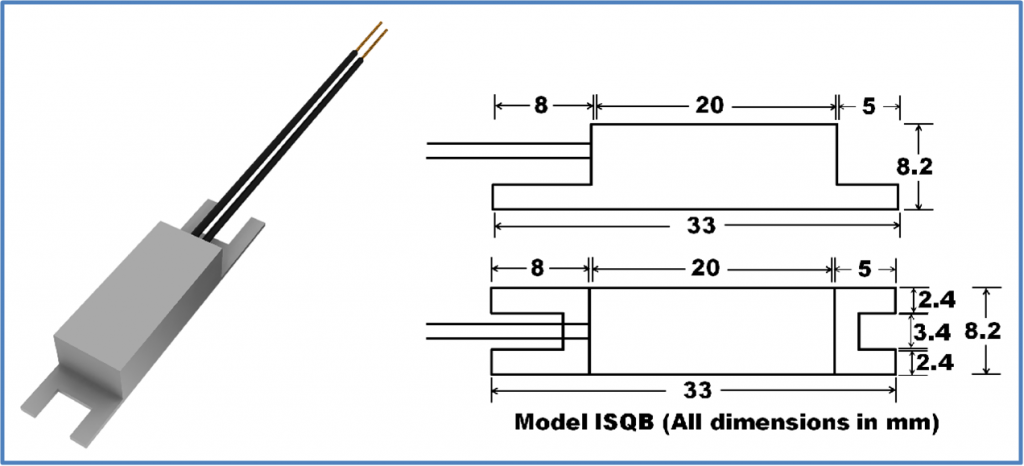

Surface Mounting Model ISQB Thermostat/Thermal Overload Protector for Transformer Protection

Transformer Thermal Protection – Model ISQB

Description of Model ISQB

Thermal Overload Protector Model ISQB is suitable for protection where space is a constraint and the thermostat cannot be fitted in the windings. The thermal cut-out can be mounted on the transformer body with two screws. It has a solid machined aluminum outer body, which provides strength and quick heat transfer for sensing temperature rise. The body is electrically insulated so that there is no chance of any electrical shock. The internal switching mechanism is based on a snap acting bi-metal which results in quick make and break. This ensures that there is no sparking when the thermostat switches off or on.

Special Features of Thermal Overload Protector:

- Easily mountable with two screws

- Insulated outer aluminum body for strength

- Snap Action bimetal thermostat

- Quick heat transfer, no chattering or sparking

- Solid silver contacts for long life of 1,00,000 operations

- High temperature teflon lead wires

Application

This thermal cut-out can be mounted on either the inside or outside of the body of the transformer with two screws. When the body heats up or the temperature of the windings rise, this thermal overload protector will sense the rise in temperature and will trip off at a pre-determined temperature. For low current and power transformers, the thermal cut-out can be fitted in series with the windings. While, for high current and power transformers, the thermal overload protector needs to be connected to a relay or a control circuit, which will switch off the current when the thermal cut-out trips off. Please consult us for complete technical guidance.

Technical Specifications of Thermostat/Thermal Overload Protector for Protection of Transformers – Model BPM

| Voltage | Up to 250VAC in primary or secondary winding |

| Continuous Load | Up to 8 AMPS |

| Maximum Load Switching Capacity | 30 AMPS |

| Switching Action | SPST Normally Closed (N.C.) contacts which open with a snap action at a preset temperature and disconnect the transformer from the mains and protect it from overheating and burning out. |

| Flash-over Voltage | Exceeds 2 KV between body & leads. |

| Endurance (Life) | Exceeds 100,000 operations (trippings). |

| Trip Temperature | Available preset for any trip temperature between 50 ± 5 C to 160 ± 5 C specified by customer. Trip temperature not adjustable. |

| Reset Temperature | Reset temperature (restart temp) approx. 15 ± 5 C below trip temperature. |

| Restart Mode | The transformer will automatically restart upon cooling. Adequate precaution must be exercised in transformer protection applications where automatic transformer restart can cause injury. |

| Fitting or Mounting | Thermostat should be fitted inside the winding. It can be taped to the winding with high temperature tape. |

Technical Specifications of Thermostat/Thermal Overload Protector for Protection of Transformers – Model ISQB

| Voltage | Up to 250VAC in primary or secondary winding |

| Continuous Load | Up to 8 AMPS |

| Maximum Load Switching Capacity | 30 AMPS |

| Switching Action | SPST Normally Closed (N.C.) contacts which open with a snap action at a preset temperature and disconnect the transformer from the mains and protect it from overheating and burning out. |

| Flash-over Voltage | Exceeds 2 KV between body & leads. |

| Endurance (Life) | Exceeds 100,000 operations (trippings). |

| Trip Temperature | Available preset for any trip temperature between 50 ± 5 C to 160 ± 5 C specified by customer. Trip temperature not adjustable. |

| Reset Temperature | Reset temperature (restart temp) approx. 15 ± 5 C below trip temperature. |

| Restart Mode | The transformer will automatically restart upon cooling. Adequate precaution must be exercised in transformer protection applications where automatic transformer restart can cause injury. |

| Fitting or Mounting | Thermostat/Thermal Overload Protector can be screwed on the inside of the body where it can sense the temperature rise and protect the transformer against burnout. If space is a constraint, it can also be screwed on to the outside, but care must be taken to protect it from external draft of air but covering it with some insulation, so that it does not get cooled by outside air flow. |

| Connections | Thermostat/Thermal Overload Protector can be connected in series with the primary or the secondary winding, whichever winding is overheating. For heavy load transformers, the thermostat needs to be connected to a control circuit, relay, contactor, etc., which will switch off the transformer when the thermostat trips off. This will protect the transformer. |